Electronic control system

The process of burning is controlled using the built-in electronic system.

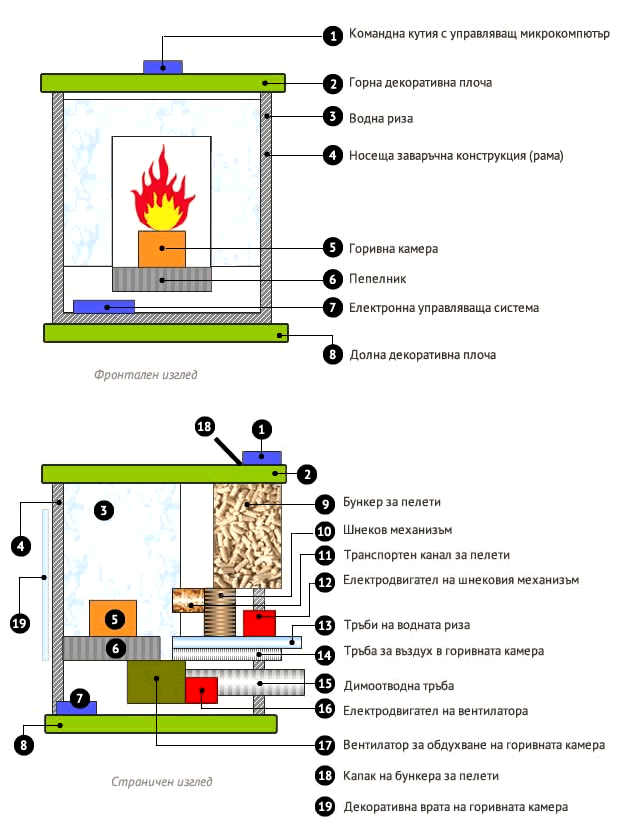

At the top of the stove is located in command box to set the current parameters of combustion and control of the combustion process. The command box is part of the microcomputer system, control of the stove.

Electronic management system consists of two blocks: display, located in the rear part of the upper decorative lid Fireside and managing block, which is located on the bottom base inside the fireplace. The two units are connected to each other with the necessary information and power lines.

The electronic system performs the following tasks:

- define, select and maintain the power of the stove;

- powered and operated motor for the venting of the combustion chamber;

- powered, manage and monitor the correct operation of the motor drive mechanism, screw conveyer;

- monitor certain internal temperatures in the stove and when they exit outside the predefined tolerances generates appropriate corrective actions;

- protecting and providing safety of shafts stove in incorrect handling of user;

- submit appropriate messages in exceptional events leading to errors in the work of the stove;

- provides a programming service of the combustion process.

Settings and mode of operation of the stove

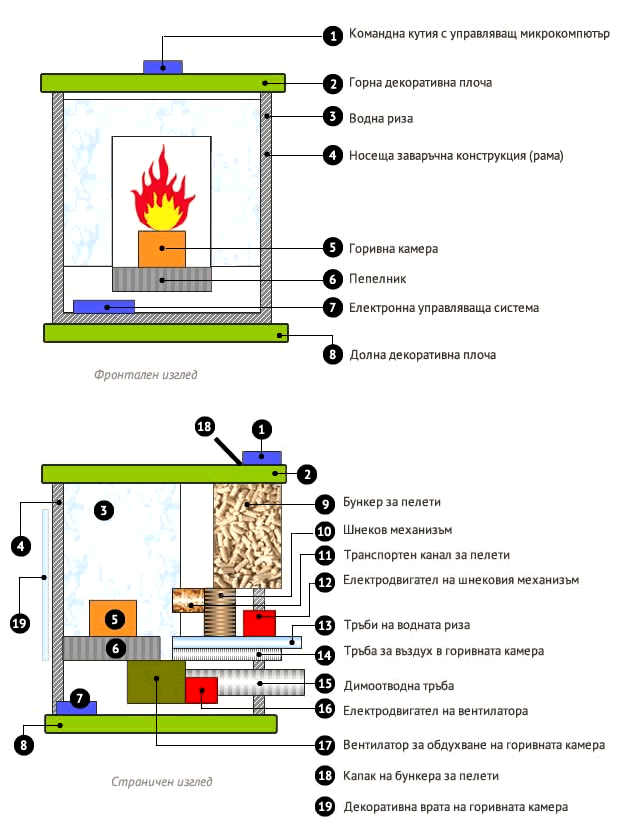

The power of the stove can be changed in nine grades ranging from 1 to 9. Each level of power is associated with a flow of air that ventilates the combustion chamber, the low rate is that in 1st grade, and the highest in 9th grade. Provision of prescribed flow-rate is accomplished by changing the speed of rotation or the power of the drive motor.

In order to achieve a power of the stove, it is necessary to burn a certain amount of pellets per unit time. The increase in power is achieved by increasing the quantity of fuel supplied. The fuel is fed through the periodic rotation of the screw mechanism that transports the pellets from the hopper to the combustion chamber.

The Auger is driven by electric motor with reducer. Operation of the engine is periodic, with two phases: stroke and pause. The move is depending on the degree to which working stove. The power is changed by changing the time during which work the Auger mechanism. This program can be adjusted for an unlimited number of times on request, with a view to optimizing the process. The experience and knowledge of the manufacturer indicated that the optimal ratio of capacity between the 1st and 9th grade moves from 1: 5 to 1: 6, which in most cases is completely satisfactory. The construction of the stove allows the receipt of greater ratio (up to about 1: 7), but it is tied to the quality of the pellets.

The command box is located at the rear of the top decorative plate on the stove. Its purpose is to implement the switching on and off of the stove, start and stop the burning process, setting up and management of all the functions, as well as servicing of the stove.

Economy, safety and securituy

The electronic system is designed to work with the minimum possible cost of electricity using modern element base and cutting-edge technical solutions. Thus is the stove adds to the energy saving systems and apparatuses.

The electronic system is designed so that it can ensure the trouble-free continuous work of the stove on 24 hours a day within the heating season – 6 months.

When the network voltage operation of the stove is suspended, if it is not equipped with a cigarette lighter and a weekly programmer. If the network voltage is established the stove in position. To recommence its work must be lighted again.

Dependence on the presence of mains voltage is an advantage in terms of safety of operation. Since dropping the network voltage circulation pump in the heating Highway stops operating if the stove continue to work, would have created the conditions for overheating of the water in the water jacket and repeatedly increasing pressure due to the steam phase. In this sense, the dependence of the network and the suspension of work in the absence of mains voltage can be regarded as a defensive feature of the stove.

The system provides the required custom features-measuring, set, monitor and maintain the desired temperature in heated premises, able to compile user programs for work of the stove at the power level or the value of the temperature in the day time zones, and also for the current week.

Optional

Optional